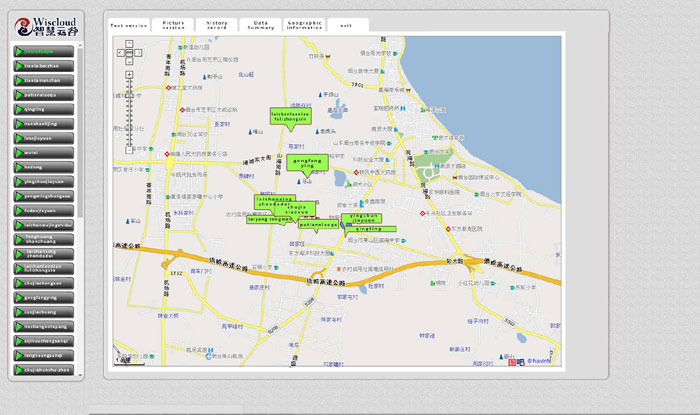

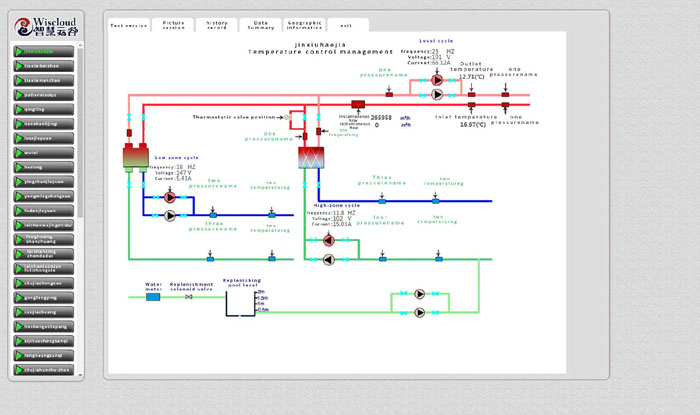

Wiscloud has established a set based on the Internet of things technology of cloud computing energy management control and service system, analyzing software data center, intelligent terminal and various management calculated by the cloud, the system will Thermotics Inc heat exchange station and public building control system real-time connection, data acquisition, storage to the cloud computing center database, management personnel may through monitoring the wisdom Yungu cloud platform, and the operation of data query, statistics, analysis, also can give the control instruction, adjustment of the operating parameter and so on, through wisdom Yungu heating control system, can provide professional and efficient services for the Thermotics Inc, but also for the Thermotics Incs control, energy saving analysis provides the basic platform, greatly reduce the cost of operation and management. Running status through cloud computing and control center to monitor the whole city and even the countrys net, street lamps, electricity, gas and other public service facilities and can be controlled by computer, mobile phone, tablet, whenever and wherever possible.

After the installation of energy-saving control system, energy saving about 20% per square metre, the winter heating coal consumption per heating quarter of every square metre is 22.5 kg, according to 1 tons of coal can produce 5000 calories per square metre computation, calories consumed per heating quarter 112.5 kcal, the installation of energy-saving control system per heating quarter per square meter will be save 22.5 calories, which can save 4.5 kilograms of coal. According to each save 1 degrees (KWH) electricity savings of 0.4 kilograms of coal corresponding calculation, will save 11.25 degrees (KWH). So every heating season every 1000000 square meters will be saving 11250000 kwh of electricity. There are 50 heating station every 1000000 square meter, a heating station water pump power consumption is about 500 kwh, the installation of energy-saving control system will save 30% of the electricity, saving 150 kwh, a heating season heating station pump will save 21600000 kwh of electricity. So every 1000000 square meters per heating season to save 4500 tons of coal, in accordance with each save a ton of coal national subsidy 300 yuan, the price of a ton of coal is calculated 1000 yuan, subsidies and coal saving value for a total of 5850000 yuan.

Using cloud computing as the core of the Internet of things and energy-saving automatic control system, heating companies do not need to build their own data center, without the need for optical access and apply for a fixed IP, only need to have a computer with an Internet connection to the heat exchanging stations and the users real-time data acquisition and control.

Control of the heating network terminal without guards well to achieve automatic control of the heat exchange station equipment, improve the heating quality. On the premise of satisfying customer demand, saving a lot of manpower, material resources, reduce unnecessary waste. At the same time, managers can more clearly understand the operation data of each heat exchanger station, make the management more accurate.

To control the heat balance, can balance the users at room temperature, avoid the imbalance of heat supply network, the vertical imbalance caused by the user, the user the uneven phenomenon. To avoid the cold user standard, causing heat users over temperature, resulting in energy waste problem. Effectively improve the efficiency of the operation management of heating and thermal system, and effectively improve the companys benefit.

Through the unified cloud computing platform monitoring to each heating stations heating state and city residents in the temperature condition, so it can be very good to the heating company supervision of heating, if it is found that the heating anomalies can inform the heating company, effectively improve the government supervision and work efficiency, creation of the government services for the peoples image. At the same time a positive response to a national energy saving and building wisdom city call.

<

<

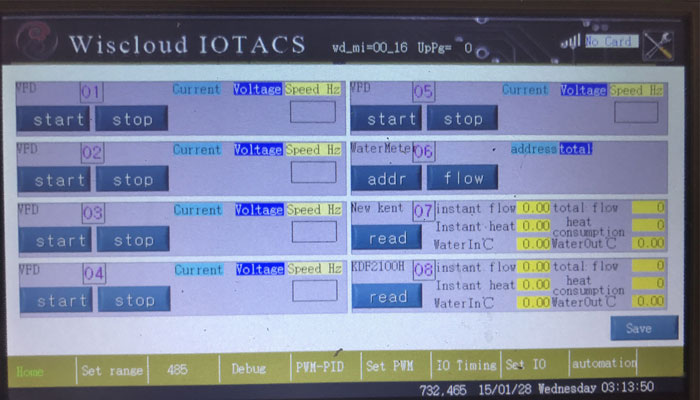

1、Touch screen terminal advanced: the Internet of things technology based on single chip microcomputer touch screen terminal, real-time display of process flow diagram picture and dynamic parameters, can be in the scene view condition and immediately set. Touch screen terminal can guide the heat source operation index, running state real-time monitoring network, can be completed on the setting parameters, load forecasting, analysis of operation and scheduling of heat to achieve heating balance network.

2、Data communication of advanced: wireless communication network, not laying cable and central heating system. This system uses the communication mode of GPRS wireless network is the best choice to realize the remote data communication. The communication mode using the data channel of mobile phone networks for data exchange, this network consists of mobile or Netcom Communications provider is responsible for construction and maintenance, the initial investment cost is low, each heating stations need to be equipped with a wireless network access equipment, system most vendors offer, the control center needs to have a public fixed IP address or domain name.

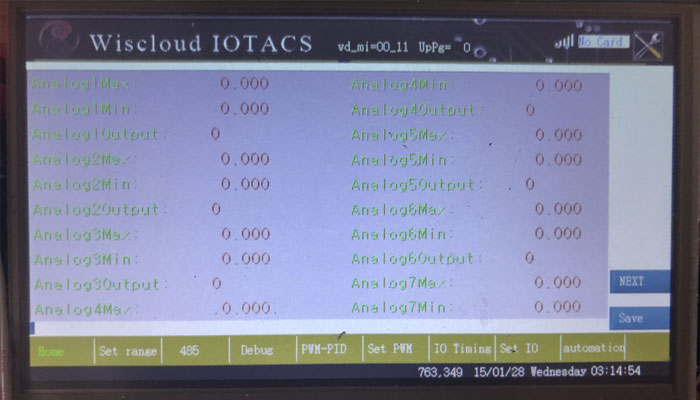

3、Strong compatible ability: based on Internet of cloud computing technology, compatible with all the equipment and the operating system and computer, tablet, phone, etc.Through the device anywhere on the network running status monitoring and control.Dont need the user build data centers and server, do not need to be independent IP.You just need to adjust the upper machine parameters is compatible with all the ModBus or support 485 communications equipment.You just need to in the client Settings for the equipment of different brands and agreement on the spot to obtain parameters and control.

4、Control terminal strong: administrators can in the PC (any) set of system parameters, optimization operation monitoring center unified guidance of sending outdoor temperature of the thermal station. At any time on the terminal of each sensor is set, the control terminal sends an instruction can be executed immediately and immediately sent to the terminal.

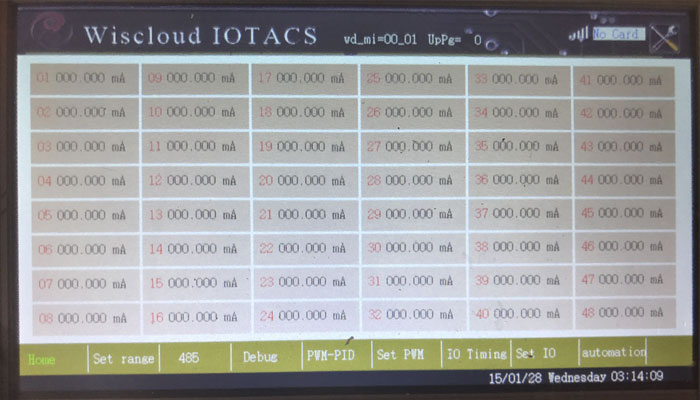

5、Powerful control load capacity: Modbus communication model based on a single device, can control the 64 inverters, flow meter, heat meter and so on all devices supporting ModBus. Each terminal device can load 24 temperature, pressure, water level sensor. Operation state of single line series can be connected and get all the equipment and the host computer to control the device.

6、The utility of high: to shorten a hydraulic balance time, reduce labor intensity, improve the heating quality. To avoid large fluctuations in a network of electric control valve opening, reduce a Guan Wang running oscillation, to extend the operational life of Guan Wang. According to the specific needs of heating companies and users, provide a variety of heating ways, for industrial users, ordinary users (radiator), territory tube heating users to provide personalized solutions, to ensure the practicality of the system. Meet the intermittent heating and billing according to the flow requirements, achieve the purpose of energy saving, create economic benefits and social benefits for owners.

7、Stable and secure database: platform can receive real-time alarm information of the thermal station with cloud computing, to remind the operator to alarm processing, recording alarm information, form the alarm log. According to the different user permissions management, on site and remote control to set the parameters adjustment, collect the data information based history database and management database.

8、Personalized service: provides the evaluation index of heating network, provide the required to predict the operation analysis and parameters of the various temperature, pressure and flow distribution graph and generate standard pressure diagram, carries on the analysis comparison of similar parameters.